Forum Replies Created

-

AuthorPosts

-

December 10, 2016 at 8:11 pm #20986

rayray07Participant- Newcastle

- 6.0L VK In the build

View build HERE

Posts: 41Been a little quiet on here the last few months, been getting absolutely raped at work.

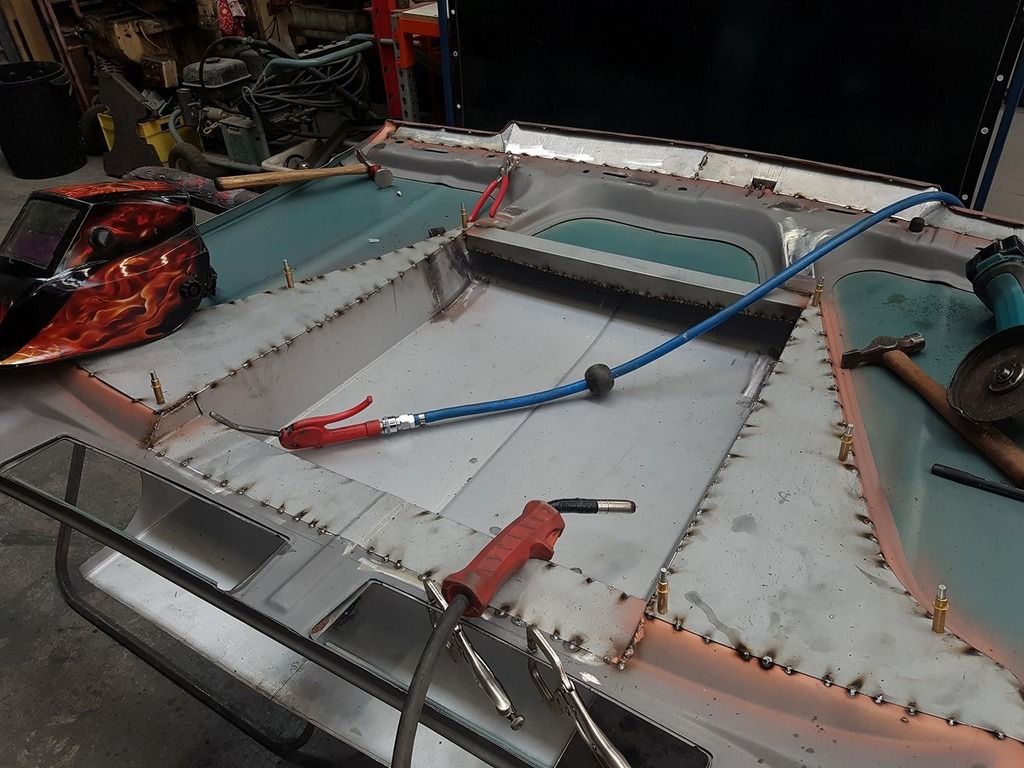

Anyway, there has been a slight change in direction with the build. The original plan of doing the conversion and cleaning it up a little has now turned into a full bare metal resto. The car has just been through Imperial Blasting at Cardiff and is now down on the central coast at Charmhaven Custom Paint & Panel where it will be until early next year. Plan now is to go with the Calais look (not badging it as one as I’m a little funny about that) with a dark silver over lighter silver of some sort. Just picked up the bonnet from Showtime Garage in Warners Bay where it got a custom sheet metal 3″ reverse cowl, The boys there blew my expectations out of the water, they went to town on the bonnet cleaning and boxing everything up, it is amazing. Only depressing thing is that I’m about to go away again with work until may/june, which means I cant rip into it until then. It’s safe to say I have pulled the pin on having a budget now.

September 24, 2016 at 1:56 pm #19875

rayray07Participant- Newcastle

- 6.0L VK In the build

View build HERE

Posts: 41Mate I love this car. Makes me just want to finish mine already. Not really good about the PWR Radiator, Hope I don’t get any issues with mine. How did you end up going with the exhaust/brake line issue?

August 18, 2016 at 6:58 pm #19116

rayray07Participant- Newcastle

- 6.0L VK In the build

View build HERE

Posts: 41That exhaust looks nice mate. Pretty much exactly what I am going to do. What mufflers dos you use? Straight through?

August 10, 2016 at 11:25 am #18955

rayray07Participant- Newcastle

- 6.0L VK In the build

View build HERE

Posts: 41gtrboyy,

yeah it’s just a chopped down VN axle and looks like it had been turned down. I bought the diff like that, I can’t really say how they hold up, but from what I’ve heard/read cut down and resplined axles are never going to be as strong as original. In the end I just went with the safest option and went 31 spline.

August 8, 2016 at 3:42 pm #18921

rayray07Participant- Newcastle

- 6.0L VK In the build

View build HERE

Posts: 41Thanks Vhman, I didn’t even think of checking it against the drawings that came with the radiator. Too late now though, rad support already modified. I was originally going to run twin system, but it was just going to be too tight and was going to cost me more for the pipe.

Dave, that’s just my fuel reg and filter mounted up there. I am just running a walbro GSS342 in tank pump. Heard of a couple guys running this setups with no issues, so I’ll see how it goes. I am the same with the tank, want to keep standard tank. If I run into dramas, I will probably run a surge tank in the boot. You don’t have the pictures of your 3.5″ system at all Dave? Would love to see how you ran it.

July 21, 2016 at 6:21 pm #18636

rayray07Participant- Newcastle

- 6.0L VK In the build

View build HERE

Posts: 41Been a little while since last update, I’ve been a little slack.

Managed to knock over a lot of the little things I have been avoiding as well. Headers came back from modification and now fit nicely, I may need to modify the 3″ collector though as it is now at a different angle. I thought I would throw the CRS 1 7/8″ back in and see how they sit with the motor in its final position and after a little more tweaking, they actually sit in nicely. I will just need to get some slip-on collectors and build the last section of the headers around the chassis rail, This I will do after it’s on the road as I don’t think some of the clearances will pass engineering.

I also decided to rebuild the diff, I was just going to run the diff with flogged centre until I had a little more money to do it properly, but with a decent tax return this year I decided to get Con from Diff Technics to sort me out with 31 Spline LSD and axles with all new bearings. Highly recommend Diff Technics, I spoke with a lot of Diff places and for price and customer service Diff Technics was far better, After sales service was aweome as well, Con helped me out a lot as I built the diff myself. Now I shouldn’t need to worry about breaking any axles. You can see in the pictures just how much the LH cone was flogged out.

I had the diff dummy fitted to check clearances for the fuel system, I got the fuel system all fitted up and I am just waiting on some 90 degree AN fittings to run the fuel hoses. Only issue I ran into was that there was no room to fit up the charcoal canister, but it should fit nicely under the LH front guard.

On the cooling side of things, I found a radiator hose that will be suffice for the upper hose (Mackay PN. CH1605). I haven’t got one for the bottom hose yet, but will suss one out. Finished boxing the radiator support to clear the SPAL Thermo. For the steam pipe I tapped a hole into the top of the water pump and fitted a 90 degree brass NPT fitting and modified the steam pipe outlet to route the hose a lot neater.

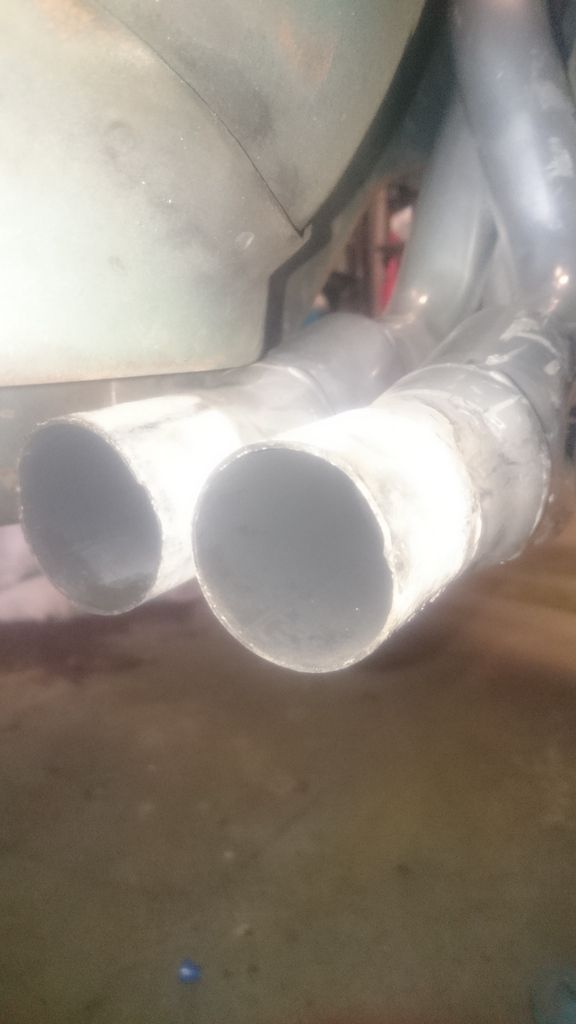

Made a bracket for my Moroso oil catch can as well. I may re make it as it has a little flex in it that I’m not really liking. Cut hole in firewall for the engine loom and found a nice spot to mount the ECU up under the dash next to the fan box. The engine fuse/relay panel fits perfectly behind the LH kick panel and now playing around with the chassis fuse/relay box, I ended up finding a good S/H fuse panel and repined into that and cleaned up the wiring, but now looking at my original idea of getting an aftermarket fuse panel so I can flush mount it as there are limited places I can fit it. I have just got all the bits in for my exhaust, going to run twin 3″ out of 3″ cats and merge straight into single 3.5″ into Magnaflow 3.5″ mufflers in standard locations. All is 304 Stainless.

I am now at the stage of pulling the motor and box out, finish cleaning engine bay and painting everything. All I need to do now is pull my finger out and get stuck in. Sort of sucks as I am about to go away with work again for about a month.

July 18, 2016 at 10:00 pm #18557

rayray07Participant- Newcastle

- 6.0L VK In the build

View build HERE

Posts: 41I am interested in just how close your rear brake line is to the exhaust, I have routed my new brake hard line in the original position. I think I have a little more than a fingers width, but I haven’t spoken to the engineer about it yet either. I’m assuming your clearance issue is under the car inside the chassis rail where your header collector is?

June 8, 2016 at 6:21 pm #17662

rayray07Participant- Newcastle

- 6.0L VK In the build

View build HERE

Posts: 41Yeah pipes should be fine once they’re modified. I’m running an E38 ECU and going to make up a bracket for it and weld it behind the firewall somewhere, should be plenty of room for access since the A/C unit is now gone. Fuse box will be in the glovebox or on the firewall next to the ECU if there’s enough room and I’ll find somewhere for the OBD2 port, maybe just up under the column somewhere.

June 8, 2016 at 8:56 am #17656

rayray07Participant- Newcastle

- 6.0L VK In the build

View build HERE

Posts: 41Nah mate, ripped all the aircon out. I did think about keeping it, but then realised that I never use it anyway (even in my daily). Windows down aircon is fine with me. Haha yea im hearing you on that, im so happy I took the time to label all the plugs and connectors when I ripped it out. Once I got my around the circuitry it was pretty easy.

I also ended up making a box section for the radiator support, the engineer was happy with that.

June 7, 2016 at 3:02 pm #17632

rayray07Participant- Newcastle

- 6.0L VK In the build

View build HERE

Posts: 41Thats a mint looking VK mate, love to see more pics.

June 3, 2016 at 7:47 pm #17511

rayray07Participant- Newcastle

- 6.0L VK In the build

View build HERE

Posts: 41Finally found some time to post an update.

OK, so back to my header issues. Gary (VRSenator065) sorted me out with his old pacemakers he had on his 454, thanks mate. Bonus with these headers was that he had modified them to exit with a 3″ collector which suited me perfectly. Now, these headers did free a stack of room up around the steering shaft and both rails, but unfortunately my issues weren’t completely solved, the 2 outer pipes of the headers were fouling on the rails under the car. To get the pipes to clear, I had the gearbox crossmember space approx. 20mm lower, but this threw out my driveline angles quite a bit. Because I will be away for work for a couple weeks, I had decided to get Dan (from Nitro Danns here in Newcastle) to come have a look and take them away for modification, we decided to drop the outer pipes 15-20mm to give enough clearance from the rails. After speaking with the engineer and the guys from muscle garage, I think it just came down to the tolerances in the chassis when it was built in the 80’s. I just want this headers headache to go away.

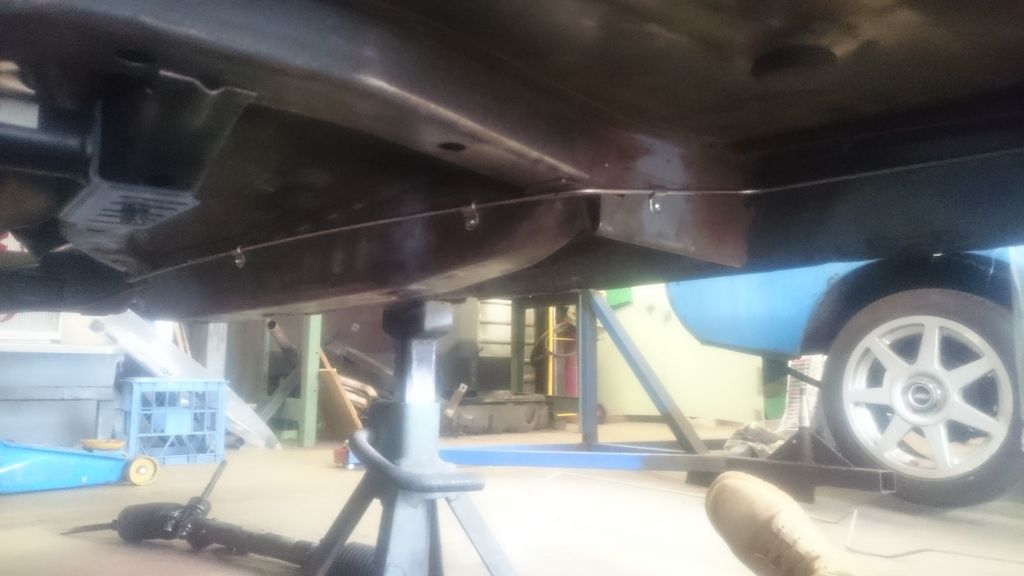

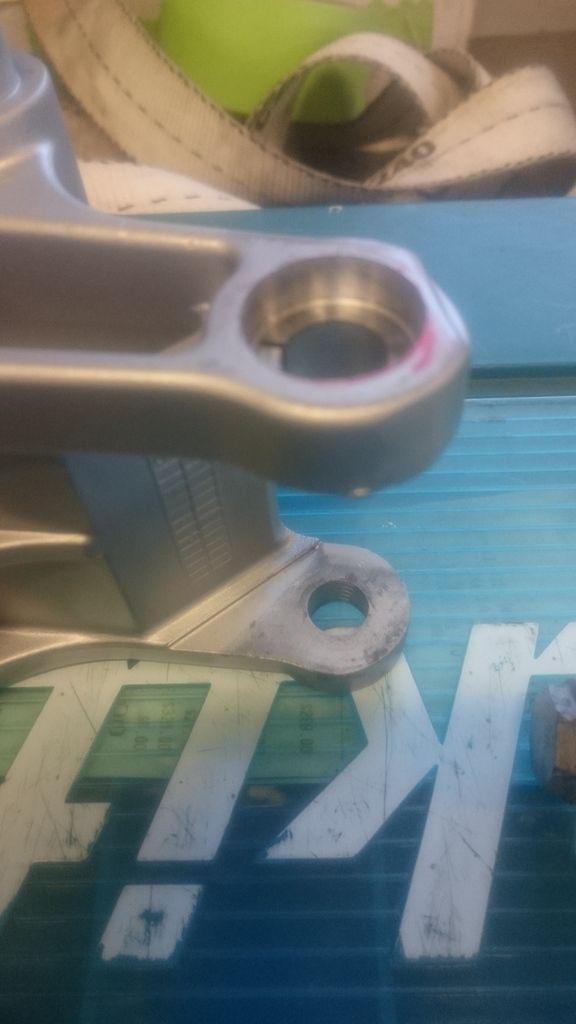

I got few other things done during the last couple weeks as well. I made up the rear brake hard line and the fuel hard line, I just need to wait to get the diff dummy fitted to check clearances for the rest of the fuel system. I modified the alternator bracket and bolt to clear the accessory belt, I ended up milling the bolt hole approx. 5mm and a few mm off the head of the bolt. I also had to lathe an old socket down to fit in the hole, I still need to space the pulley out a little more to align everything. Also has plenty of clearance from chassis rail when fitted up.<b></b><i></i><u></u>

Got the body wiring harness sorted out as well, ripped out all the unnecessary circuits and wires. I am going to wire in a new fuse block that’s a lot more compact and look at mounting it in the glovebox or on the firewall. I am very surprised at the condition of the 30 yr old harness, only thing I didn’t like was all the tape. I have ripped all the tape off and have heat shrunk all the splice joints and will wrap it all in bi-seal once I have fitted it up neatly.

Here is what I pulled out.

May 17, 2016 at 3:50 pm #16959

rayray07Participant- Newcastle

- 6.0L VK In the build

View build HERE

Posts: 41Mate, looking real nice. I’ve also gone with an ultimate Street Shifter, I cant say much on it as my build is far from a road test. Interested to know what you think about 3.9 gears, im running 4.11. Love the build though, that sleeper look is mint. Let us know how you go with engineering.

May 15, 2016 at 9:35 pm #16908

rayray07Participant- Newcastle

- 6.0L VK In the build

View build HERE

Posts: 41Thanks Judge1, after looking at that I might look at doing that or just fabricating one up. It does look a lot neater than just cutting a section out like I have already done.

May 14, 2016 at 7:13 pm #16851

rayray07Participant- Newcastle

- 6.0L VK In the build

View build HERE

Posts: 41Haha it’s ok, jokes on me. I’m hearing you mate, I actually spent most of the day with the oxy torch and managed to free up a heap of room on the drivers side. I ended up separating the pipes and also managed to drop the motor down a little more. At the end of day, I got the pipes to fit with clearance, but there is just not enough and I can’t see an engineer signing off on it. Even if it did pass engineers, I personally don’t like the clearances and the shape of the pipes now after modifications, any slight movement in the mounts or drivetrain down the track would result in something fouling. Very annoyed I flushed my money down the drain with these headers and I don’t recommend them to anyone.

VRSenator, I am very interested in your headers and I will PM you about them. You have already done exactly what I was going to do with the 3″ collectors.

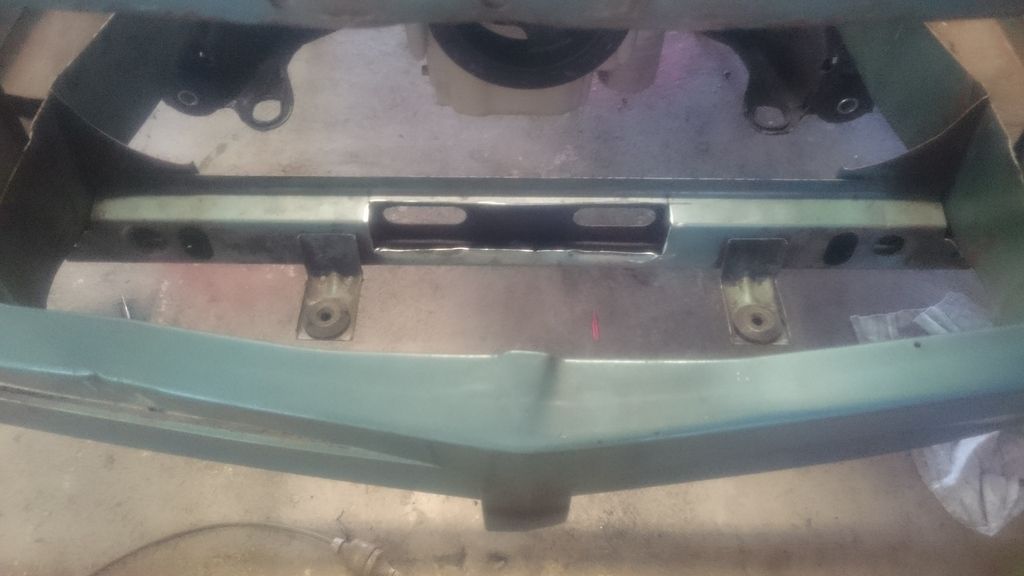

The Radiator sits in fine, it’s just the thermo that fouls at the bottom, I ended up just taking a section out of the rad support and now it all sits in fine. I might box it up, but it still has good structural integrity as is. Also opened up a bit more room around the bottom radiator pipe.

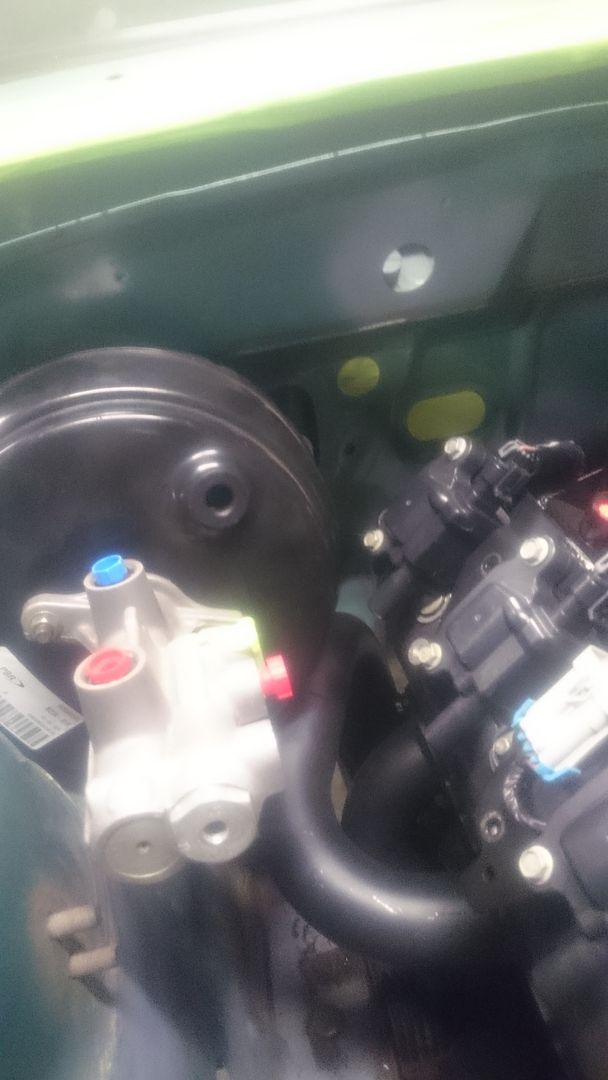

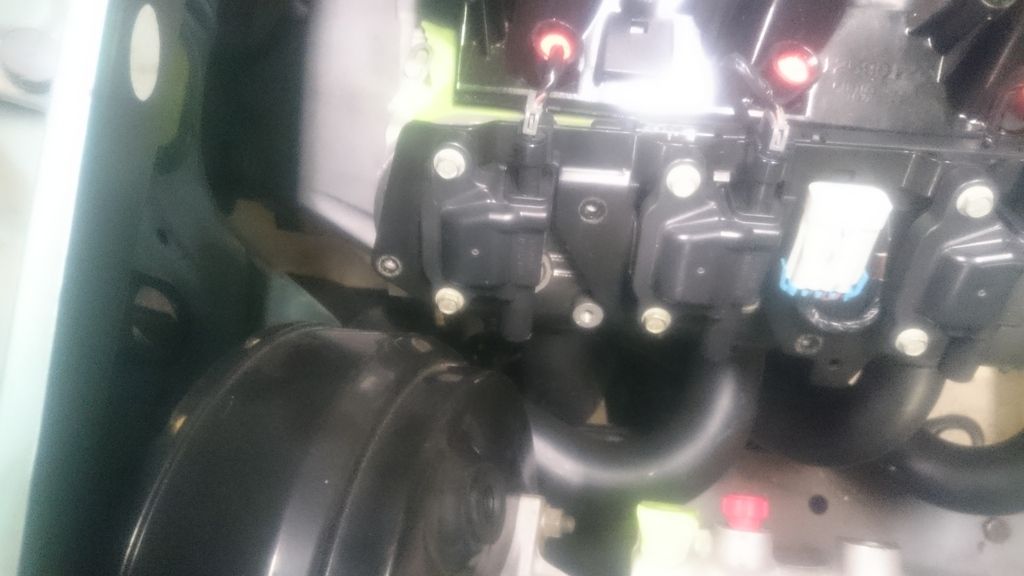

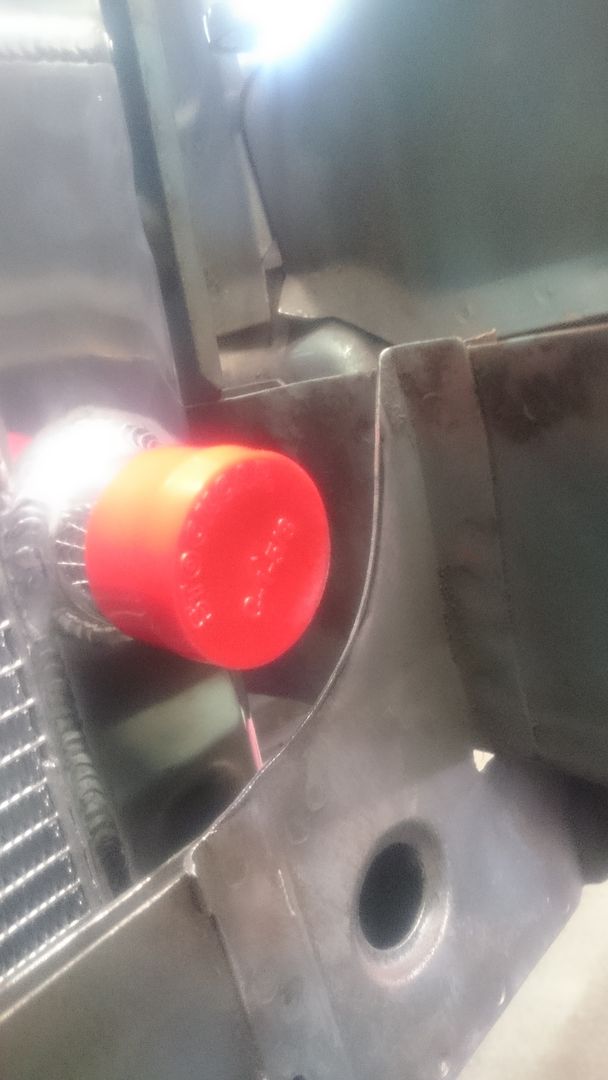

Onto what else I got done today, dummy fitted the brake booster and clutch master. Now, I ended up using VT booster and master, I fabricated the firewall bracket so it pushed it as far over to the drivers side as possible to clear the coils, which is does. Only problem I encountered was the booster was just touching the clutch master refill cap. I just needed to space it out about 5mm.

May 14, 2016 at 8:43 am #16842

rayray07Participant- Newcastle

- 6.0L VK In the build

View build HERE

Posts: 41Yeah mate, its a joke. CRS need a serious look at there quality control. I have seen these headers fit a few cars, but even if I drop the motor to sit on the K-frame, the collectors would still hit the floor.

May 13, 2016 at 8:21 pm #16826

rayray07Participant- Newcastle

- 6.0L VK In the build

View build HERE

Posts: 41Does anyone have some pacemaker conversion headers for sale??

That’s how good my day has been with fitting these CRS headers. I knew there would be some modifying to be had, but not to the extent I’m going to need to do to get these headers to fit. I wish I had listened to everyone and just gone with the paceys. Just to get these headers up into position, I had to chop the collectors off and once they were in drivers side pipes foul on engine mount, brake booster and intermediate shaft in 2 different places. Passenger side is a bees dick from the rail and where they bend to straighten out under the car, they exit straight onto the chassis rail (why I had to chop it). The good/stupid thing is, is that there is plenty of room for the pipes to clear everything, but are just all routed incorrectly. I will attempt to fix them over the weekend with the oxy torch, but I’m starting to think I might just try find some paceys.

On top of all that, the SPAL thermo mounted on the radiator fouls on the radiator support. It’s not too bad, I will just need to push the bottom of the radiator forward about 10mm.

Ok, thanks Dave. I’m running E38 ECU as well, but will be mounting it behind the firewall.

Some pictures.

May 11, 2016 at 11:43 am #16787

rayray07Participant- Newcastle

- 6.0L VK In the build

View build HERE

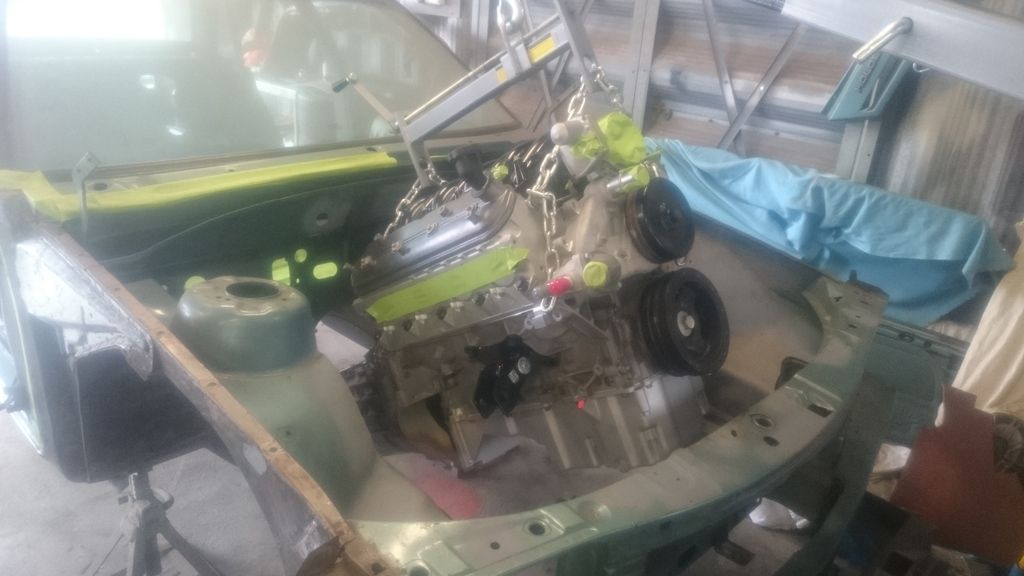

Posts: 41Yes indeed, it was good to see the motor in bay, the build starting make some real traction.

Back to the headers though, I have fitted headers and to my surprise there is plenty of clearance from the rails. Only real issue is the collectors hitting the floor, stopping the gearbox fitting right up into the tunnel. The pipes will need to be heated and bent down a little, collectors need to move approx 1″ down. The intermediate shaft and Drivers side engine mount are a little close for my liking, but should open more room up once I can get the box up into the tunnel properly. Overall, I don’t see any major mods to be done to the pipes at this stage, but ill have to wait and see once I get the gearbox in its final position.

Getting the headers in initially was an absolute nightmare (as expected), how I did it was hoist motor and box in feed headers up from underneath then bolt k-frame and rack up, it probably wouldn’t have been as hard if the collectors weren’t hitting the floor which was actually stopping me from bolting them up in the right position. Only advice I can give is make sure you don’t have your new spark plugs fitted, I broke 2 of them, and have lots of patience. I did kick the passenger side header across the floor at one stage Haha.

I also spoke to a guy from muscle garage about the TuffMounts I bought from them, he was more than happy to help out which is much more than I can say about CRS. CRS wouldn’t help me out one bit with fitment. Bloke from muscle garage says TuffMounts push motor to passenger side 10mm and are designed to angle motor/box back 3 degrees, also said get the motor level and square first then get box up into tunnel. The TuffMounts bolt holes to the motor are horizontally slotted and are there to compensate for different chassis/k-frames, so the mounts don’t have to be bolted up in the same position which is what I assumed and couldn’t get the motor square. Last advice he had was you should just work on getting your motor/box positioned and angled correctly and then just get custom headers made which I now wish I had done, aaaaannd CRS are garbage Haha.

I do have a stack of pictures I will post up in the next few days as I am on my phone right now.

May 8, 2016 at 8:16 pm #16698

rayray07Participant- Newcastle

- 6.0L VK In the build

View build HERE

Posts: 41VRSenator065, I heard a lot of mixed reviews with the PWR rad/thermo setup, but after reading your build and how well it had worked with a 454, I couldn’t really see a 6.0L having cooling issues with it.

Haha no one is instilling any confidence in me with these headers, But I have actually spoken to a couple of guys on a FB page that got them to fit with Tuff Mounts and only a small bit of modification. Most of their issues were with the power steering rack/column. I am using manual steering as well, so I hope I pick up a little room there and I have already mocked up the headers with the rack. Only problem will be the final angle on the column and the chassis rails, but hey, if all goes pear shaped, I do love a challenge.

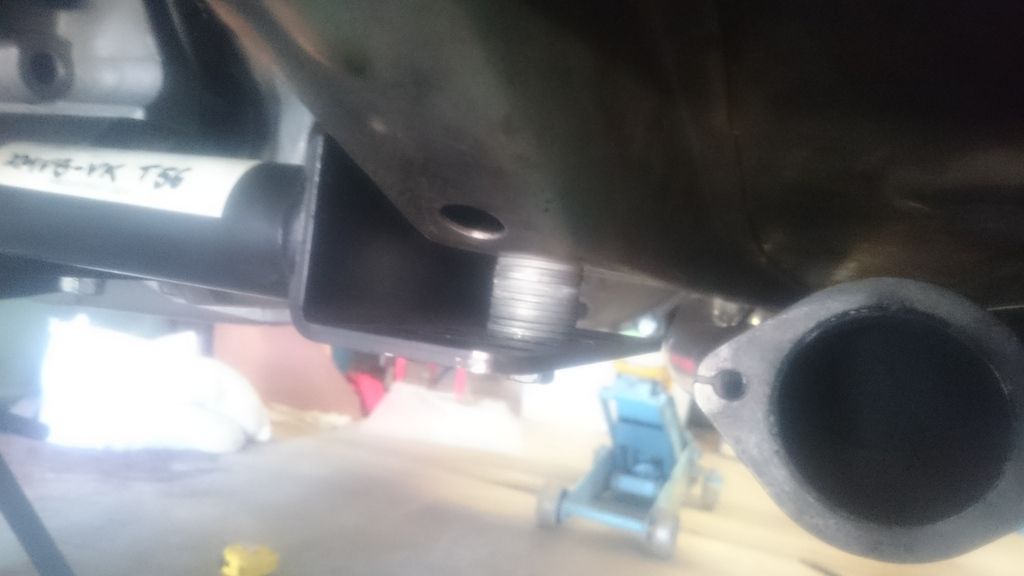

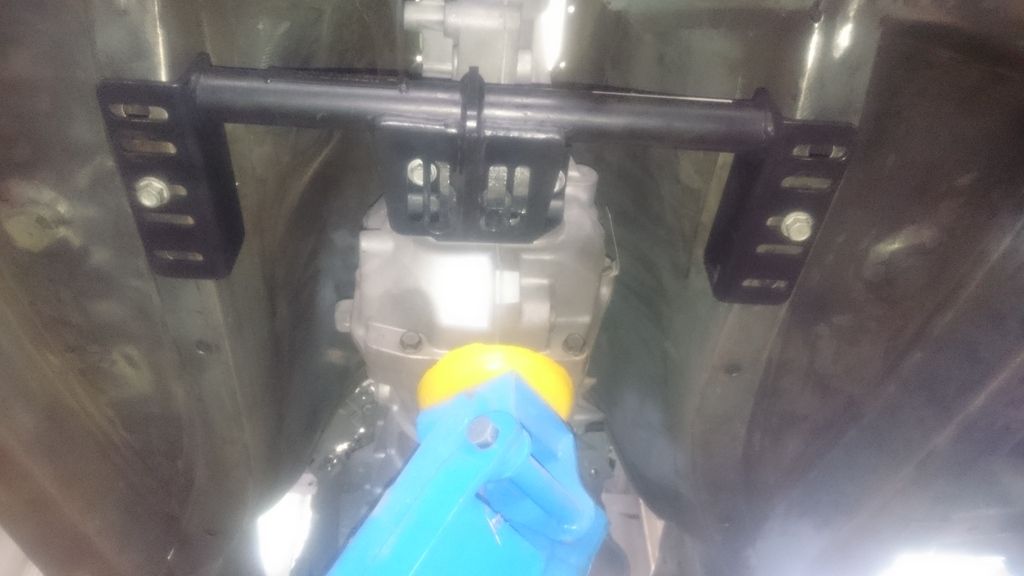

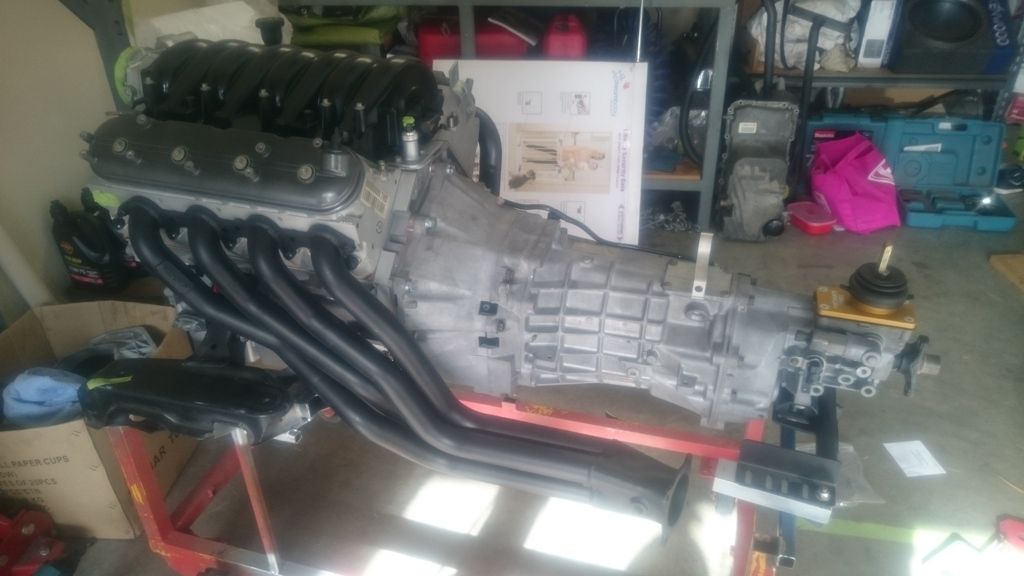

I got the motor and box in today just to get all the angles right and everything centred until I noticed the T56 cross member I got from CAE was far off the mark. It looks as if the centre mount for the box was welded offset to the wrong side and when I looked it up on their website, it actually looks very different from the LS/T56 cross member, but very much (exactly) like the 5.0L/T56 cross member. It wants to push the box way to far to the passenger side. I’m a little disappointed I had to stop there, I was really looking forward to seeing how these headers were going to fit

. Anyway, I will be calling them first thing tomorrow sorting that out. Obvious mods had to be made such as massaging the tunnel a little to clear the reverse lockout solenoid and bashing the chassis lips back to clear the headers, other than that, there was plenty of room around the back of the motor and around the box. I will dummy up the brake booster and clutch master tomorrow. I also recommend removing the shifter when fitting the motor and box, it just gets in the way and a load leveller will be the best investment you make when doing this job.

. Anyway, I will be calling them first thing tomorrow sorting that out. Obvious mods had to be made such as massaging the tunnel a little to clear the reverse lockout solenoid and bashing the chassis lips back to clear the headers, other than that, there was plenty of room around the back of the motor and around the box. I will dummy up the brake booster and clutch master tomorrow. I also recommend removing the shifter when fitting the motor and box, it just gets in the way and a load leveller will be the best investment you make when doing this job.Here are some pictures, I like pictures

.May 7, 2016 at 9:24 pm #16672

.May 7, 2016 at 9:24 pm #16672

rayray07Participant- Newcastle

- 6.0L VK In the build

View build HERE

Posts: 41Gday Dave, I’m actually trying to figure out how exactly to go about my exhaust. I had a long chat with one of the blokes from sureflo exhaust during the week about going with a single 3 1/2 ” system, But I’m still tossing up between that and a twin 2 1/2″. How exactly did you go with your single 3 1/2″? What mufflers did you use? How was it for sound/drone? The bloke I was speaking to at sureflo was pretty certain I wouldn’t get a single 3 1/2″ below 90dB for engineers. Do you have pictures or even a video/sound clip? haha Sorry for all the questions, I just don’t want to spend a heap of money and time building a system that sounds garbage or won’t pass engineers.

As for the compression ratio mate, I’m not 100% sure, But I had a play around with a C/R calculator and it bumps it up from 10.1:1 to 10.9:1. The intake lines up fine.

Cava454, The header are CRS 1 7/8″ 4 into 1. Probably a little big for a standard 6.0L, but I do plan on a S/C down the track.

I also got my stand alone loom back from Killa Kustom Kables during the week. I am very happy with the workmanship and quality of the loom, It was completely wrapped in braided sleeve and was wrapped in heat protection in the right places. Loom was built to relocate the ECU behind the firewall using all new wire, Fuses and relays were all built in and all the necessary outputs from the ECU. Only issue I had with the loom was that the reverse light plug to the box, which was just too short and was actually the wrong plug. I know a lot of guys had recommended ultimate conversion wiring, but he wanted to charge $200 more to just rip out the wires I didn’t need and keep the ECU in the engine bay

.

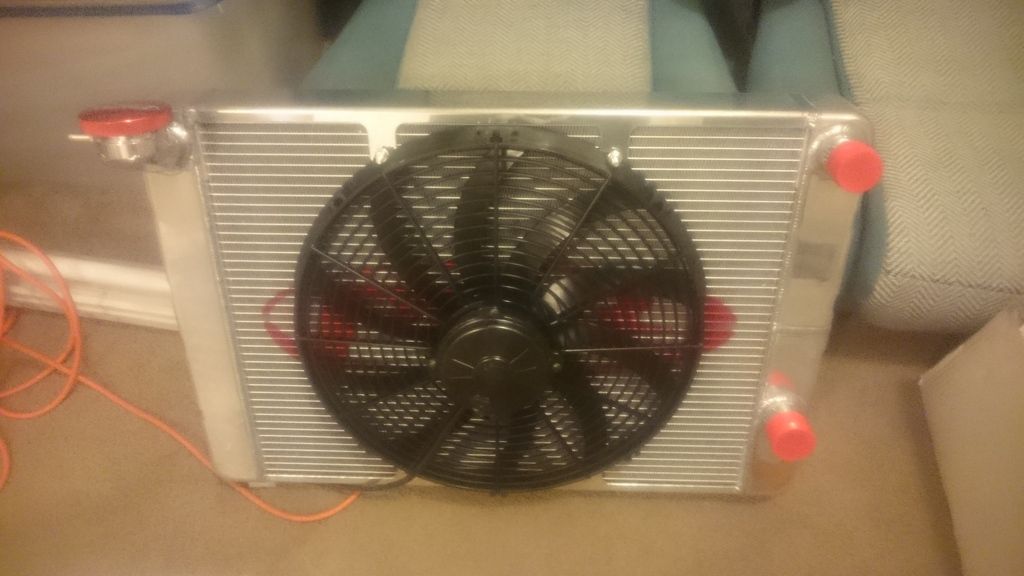

.Also, I got my radiator and thermos setup. Decided to go with the PWR rad and single SPAL thermos.

With my fuel system I decided to go with a Walbro GSS342 intank pump straight into a filter then into a WIX regulator/filter (PN 33737) with return, from there up to the fuel rail all using -6 AN hoses/fittings and 3/8″ SS hard line.

I will have the motor and box dummy fitted in the next couple days, so I will post back up on how it all went.

April 30, 2016 at 9:08 pm #16475

rayray07Participant- Newcastle

- 6.0L VK In the build

View build HERE

Posts: 41UPDATE.

Progress has been a little slow lately due to work commitments and waiting on engine parts.

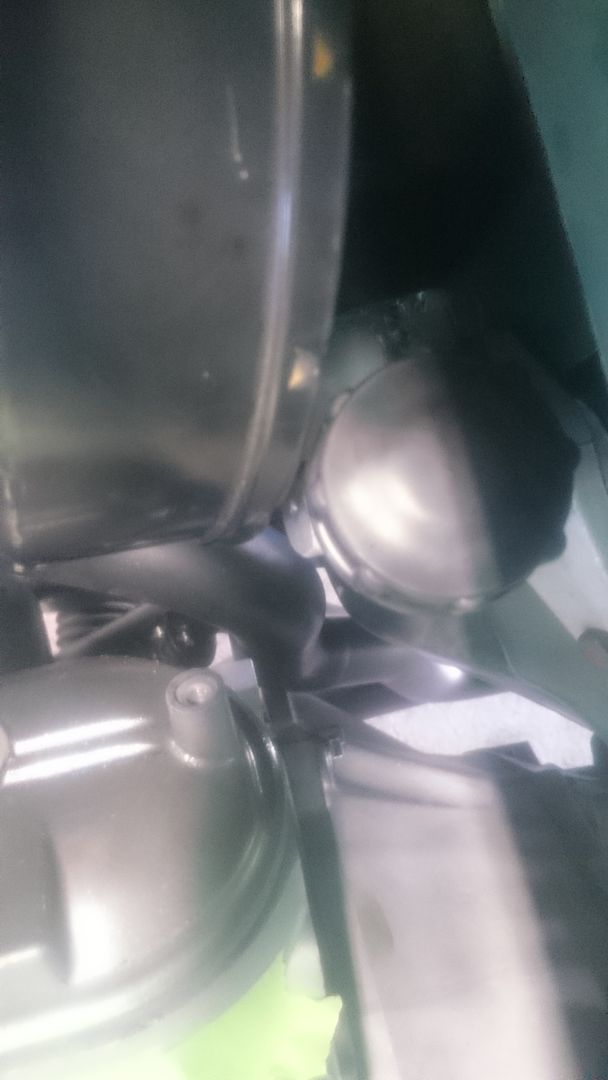

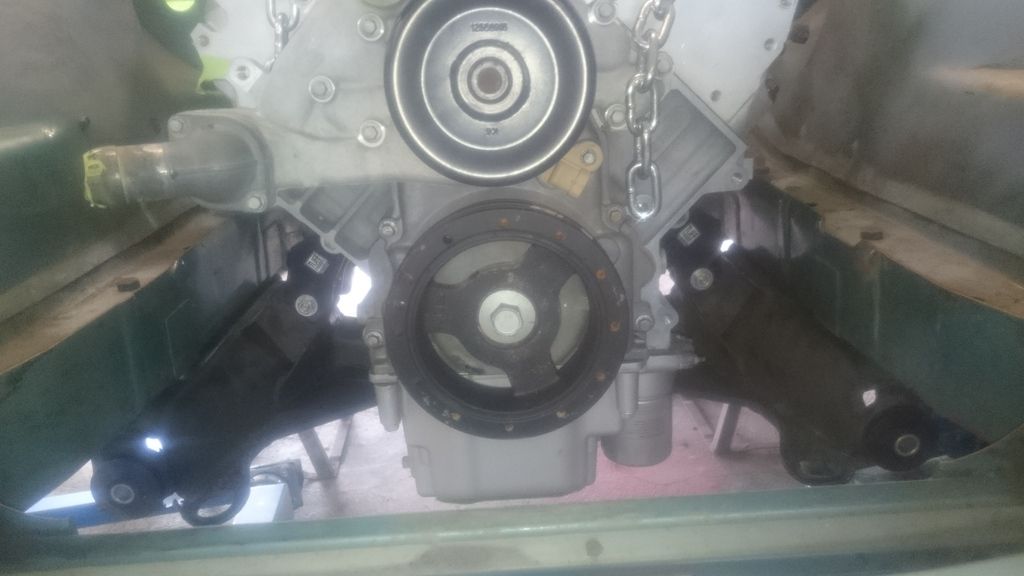

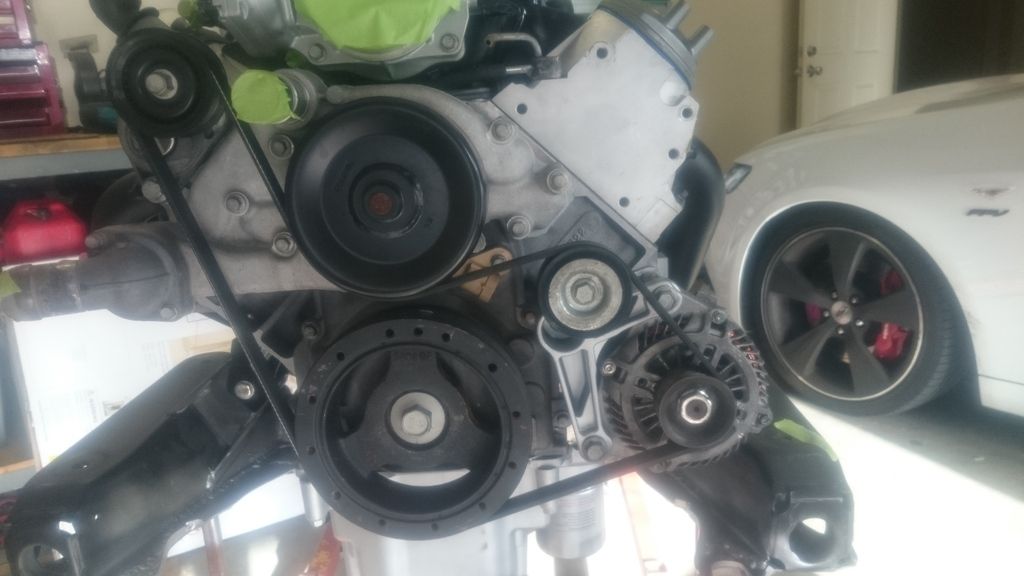

The motor is just about all back together and the car is off the rotisserie ready for engine fitment. While waiting for parts, I made up an engine/gearbox stand out of some scrap and an old damaged K-frame I had laying around. This helped me with checking all the clearances with headers, steering rack, starter ect. Very happy with the clearance around the intermediate shaft, but LH header comes really close to the starter motor terminal. RH Header have just enough clearance around the bell housing.

With my accessory drive setup, I used a Dayco ribbed belt (P.N. 5060548) and Dayco pulley (P.N. 89015). All fits well aside from the belt contacting the head of the top alternator bolt. I should get clearance if I mill the bolt section on the bracket down approx. 6-7mm and take a few mm off the head of the bolt so it will sit flush with the bracket.

I also made up the 3/16″ SS brake lines for the diff. First time I had done this and I found it quite easier than I had first thought, just don’t forget to put the tube nuts on before you do your final flare like I did :disappointed: . I had to remake the entire brake line again. I also made a tube straighter out of some scrap RHS, threaded rod and some cheap eBay bearings, works awesome and beats paying the ridiculous amount for a proper one.

Here are some more pictures of the clearances with the headers.

And for those wondering about the FPV in the background, Yes that is my ute. FPV GS Ute currently putting out just shy of 400RWKW and it is one hell of a car to drive. I was tossing up for a while between it and a VE SSV ute and I am very happy I chose it.

-

AuthorPosts