Home›Forums›Technical – General›Engine›304 Intake Manifold Swap

This topic contains 160 replies, has 10 voices, and was last updated by Immortality 7 years, 7 months ago.

-

AuthorPosts

-

July 15, 2016 at 10:48 am #18440

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Hey Hoopstar, welcome to the forum, not sure I have seen you post before. Like the HR in you profile pic, that yours?

July 15, 2016 at 11:47 am #18441

ImmortalityParticipant- 97 HSV Senator 185i 02 VX L67 Calais

View build HERE

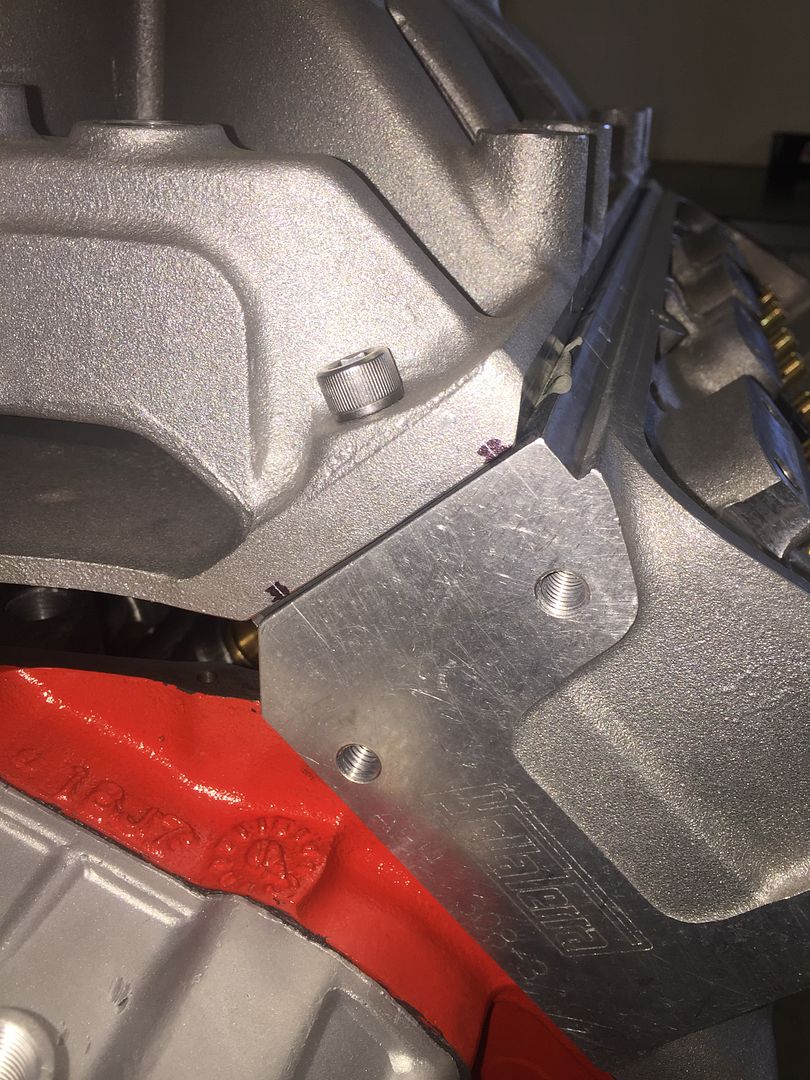

Posts: 535Did a quick fitment check today before the manifold goes off to the machinist, port alignment looks reasonably good. Those NZV8’s can’t have had much machined off the heads.

Attachments:

You must be logged in to view attached files.July 15, 2016 at 12:25 pm #18444

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Just out of interest Immortality, how did you check the port alignment, its something I have always wondered?

July 15, 2016 at 1:06 pm #18446

ImmortalityParticipant- 97 HSV Senator 185i 02 VX L67 Calais

View build HERE

Posts: 535To do it correctly requires marking out the ports and then transferring marks over to the manifold and comparing. In this case I just put it in place noted the position on the intake gaskets and fitment in the valley and then removed the manifold and checked it against the gaskets. Good enough as I’m not port matching but if you were then marking it out is the only real way. Some pics from HPE (on the AV8 forum) showing his port matching work.

July 15, 2016 at 1:10 pm #18447

July 15, 2016 at 1:10 pm #18447Like the HR in you profile pic, that yours?

Yes mate, it is mine..

That’s why I said should LOOK INTO….

</span>

Cava, sorry mate I wasn’t having a go… apologies if you took it that way..!!

It’s just that the Harrops don’t tend to suffer the (entire bank) fuel distribution the Edelbrock AG seems to possess.

Milling out that section tends to hurt light throttle response and a bit of torque, so you’d avoid it if at all possible. I am just not sure what the reason is he’d need to “look into” it.. especially since it appears he doesn’t even have it bolted on the motor yet.

-

This reply was modified 7 years, 9 months ago by

Hoopstar.

Hoopstar.

July 15, 2016 at 1:15 pm #18449

ImmortalityParticipant- 97 HSV Senator 185i 02 VX L67 Calais

View build HERE

Posts: 535LOL, yep it’s not even bolted on yet. We will check bank to bank fuelling but that is a long way off yet. Car needs to be on the road by the start of October if my job application goes well.

Car will be primarily road tuned (as I have all the gear hear for that) but it may spend a little time on the rollers as well so we may possibly run it with/without spacer to see if there is any difference as I will have a spacer. I also have a NOS big shot kit which uses a 1/2 open spacer which may get fitted at some stage too

edit: I know of another engine that had a large AFR discrepancy between banks, it had a full twin exhaust system, once they fitted a balance pipe into the system the banks balanced out (was a cammed up 304, with head work but still running banana’s).

-

This reply was modified 7 years, 9 months ago by

Immortality.

-

This reply was modified 7 years, 9 months ago by

Immortality.

July 15, 2016 at 2:12 pm #18452

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Yes mate, it is mine..

Cool as, if you want feel free to throw up a thread in the other rides section, my Kombi and and a few others are in there. I am so old a good mate of mine had a HR when I was at high school that his Dad bought new and passed onto him, good times were had in that let me tell ya

July 15, 2016 at 2:15 pm #18453

July 15, 2016 at 2:15 pm #18453

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Thanks for that, have often wondered the correct way to do it. I match ported the exhaust on mine but used the gasket as a template, after first checking the gasket on the head. With my induction they are in two separate pairs so I did the same, but the manifold was spot on.

-

This reply was modified 7 years, 9 months ago by

VRSenator065.

VRSenator065.

July 15, 2016 at 2:46 pm #18455Like the HR in you profile pic, that yours?

Yes mate, it is mine..

That’s why I said should LOOK INTO….

</span> Cava, sorry mate I wasn’t having a go… apologies if you took it that way..!! It’s just that the Harrops don’t tend to suffer the (entire bank) fuel distribution the Edelbrock AG seems to possess. Milling out that section tends to hurt light throttle response and a bit of torque, so you’d avoid it if at all possible. I am just not sure what the reason is he’d need to “look into” it.. especially since it appears he doesn’t even have it bolted on the motor yet.

haha all good mate. I’m thick skinneed.

I didn’t know what milling it actual achieved, so good to know now. Just new it helped in some cases. Esp in some SBC

July 15, 2016 at 4:32 pm #18458

ImmortalityParticipant- 97 HSV Senator 185i 02 VX L67 Calais

View build HERE

Posts: 535I didn’t know what milling it actual achieved, so good to know now. Just new it helped in some cases. Esp in some SBC

In a normal Dual plane manifold each intake port only see half of the total volume of the TB so if you have a 1000cfm TB than each port only “sees” 500cfm of flow with a small plenum volume which promotes good airspeed at low throttle openings but limits flow at full throttle.

If you mill down the divider each runner can now draw on the full 1000cfm of flow as well as increasing the plenum volume. There is also stuff with intake pulses pulling on opposite runners, gets quiet technical and I don’t understand it all either.

July 15, 2016 at 4:34 pm #18459That’s why I Brought a single plane lol

July 15, 2016 at 4:49 pm #18461

ImmortalityParticipant- 97 HSV Senator 185i 02 VX L67 Calais

View build HERE

Posts: 535Comes down to application I guess, some people say the single plane is king but when someone like TK on the AV8 forum uses a dual plane on a 365 cu race engine that shows me it can’t be all bad. Some other guy from the US says something similar and he’s kinda like the engine guru of engine guru’s…..

July 15, 2016 at 5:16 pm #18462Who you speaking of?

July 15, 2016 at 5:39 pm #18463

ImmortalityParticipant- 97 HSV Senator 185i 02 VX L67 Calais

View build HERE

Posts: 535David Vizard, Engine genius.

I’ve read some of his books, really wanted to go to his seminar when he was here in NZ but things just didn’t work out right.

July 15, 2016 at 6:30 pm #18466..And there lay another problem – the size of most throttle bodies are 1000cfm and more which is way too big for a 304 or 355.

Even with 100% VE, a 355 turning at 7500 rpm only requires a TB that flows 770cfm.

This reduces air speed and makes less torque in the mid-range.

1000cfm with 100% is nearing 10,000rpm

CRD Engineering make a 750cfm TB which is a great match for a well tuned 355.

July 15, 2016 at 6:36 pm #18467the wizard definitely knows his way around an engine and all aspects of it at that

July 15, 2016 at 6:44 pm #18468..And there lay another problem – the size of most throttle bodies are 1000cfm and more which is way too big for a 304 or 355. Even with 100% VE, a 355 turning at 7500 rpm only requires a TB that flows 770cfm. This reduces air speed and makes less torque in the mid-range. 1000cfm with 100% is nearing 10,000rpm CRD Engineering make a 750cfm TB which is a great match for a well tuned 355.

but it’s only air. Won’t the engine only use what it can take. Efi is dry induction compared to carby

July 15, 2016 at 7:07 pm #18469

ImmortalityParticipant- 97 HSV Senator 185i 02 VX L67 Calais

View build HERE

Posts: 535but it’s only air. Won’t the engine only use what it can take. Efi is dry induction compared to carby

..And there lay another problem – the size of most throttle bodies are 1000cfm and more which is way too big for a 304 or 355. Even with 100% VE, a 355 turning at 7500 rpm only requires a TB that flows 770cfm. This reduces air speed and makes less torque in the mid-range. 1000cfm with 100% is nearing 10,000rpm CRD Engineering make a 750cfm TB which is a great match for a well tuned 355.

Well then a dual plane that only sees half the flow (per bank) should be ideal then

I had toyed with the idea of a single plane and then fitting a plenum divider which I think is fairly much what the Duggan manifold is (Smitty uses on his VK racer).

At the end of the day I know that this manifold, with standard 304 heads, 10:1 comp and a small solid FT cam will make 400hp (basic NZV8 tourer specs).

-

This reply was modified 7 years, 9 months ago by

Immortality.

July 15, 2016 at 8:26 pm #18473but it’s only air. Won’t the engine only use what it can take. Efi is dry induction compared to carby

Two words: air speed.

Too large a TB will slow air speed and reduce cylinder fill (effectively reducing VE) resulting in less power.

Those calcs above were @ 100% VE. Things get worse at ‘real world’ VE’s seen on street engines.

The other thing is an engines air requirements versus rpm tend to be fairly linear but airflow versus throttle position is more logarithmic so a TB that is too large becomes worse as the blades open more and more and air speed drops.

July 16, 2016 at 2:37 pm #18476

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

+1 for David Vizard. One of my first cars 35 years ago was an 1100 Mini. Back then he was the king of Mini’s, and he has just grown and grown from there. I didn’t know he does seminars…

-

AuthorPosts

You must be logged in to reply to this topic.