Home›Forums›Technical – General›Fuel Systems›Fuel getting hot causing fuel pump noise

This topic contains 40 replies, has 9 voices, and was last updated by dave 4 years, 7 months ago.

-

AuthorPosts

-

September 5, 2019 at 6:26 pm #29686

ImmortalityParticipant- 97 HSV Senator 185i 02 VX L67 Calais

View build HERE

Posts: 534Maybe heat management in the bay needs looking at if indeed that is the culprit.

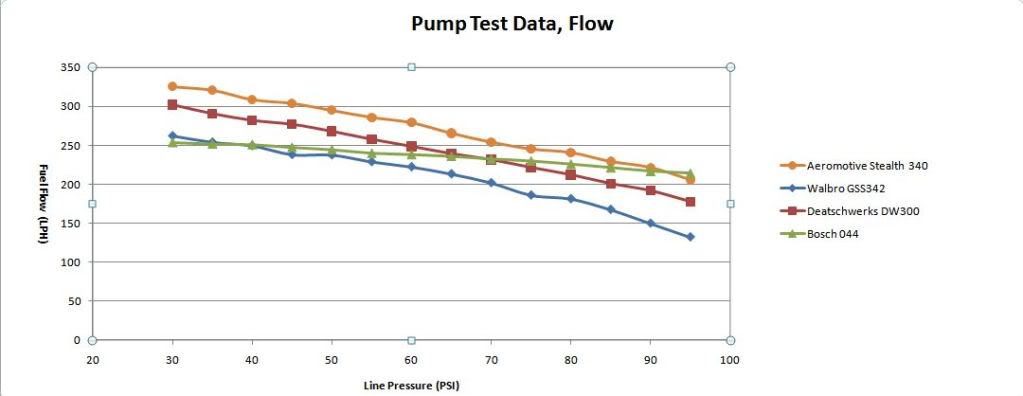

What pressure are you running? Stock they run something stupid like 58psi with the dead head setup but with a full return style a more regular 43psi would probably work better as the pump isn’t working as hard and volume is also better at the lower pressures. This is assuming you have the ability to re-tune to suit the lower pressure.

September 6, 2019 at 9:15 am #29690

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

What pressure are you running? Stock they run something stupid like 58psi with the dead head setup but with a full return style a more regular 43psi would probably work better as the pump isn’t working as hard and volume is also better at the lower pressures. This is assuming you have the ability to re-tune to suit the lower pressure.

Interesting, my tuner has mine at 60psi full return, hadn’t considered what other effects that would make. Are the injectors designed to work at a particular pressure though?

September 6, 2019 at 9:32 am #29691They do have a minimum working pressure, under that the spray pattern becomes a dribbly mess, in the past with big injectors I’ve used the base fuel pressure as an aid to tuning to get an acceptable idle, what happens is at times you run out of adjustment as the injector just flows too much at idle.

I use the Pump control to drop the pressure, this in turn lets me dial in more pulse width and the injector works fine, soon as you give it a rev the pump comes back to full speed/pressure and you have your fuel flow for top end, you can turn the reg down to drop base pressure but it limits fuel flow on the top end, you can also bump base up to make the injector “bigger” if your pump/s have enough capacity to cover it but without a pump controller you run into crap idle again.

September 6, 2019 at 9:33 am #29692

ImmortalityParticipant- 97 HSV Senator 185i 02 VX L67 Calais

View build HERE

Posts: 534Yes it depends on the injectors, I believe LS injectors are rated at 4 bar, I believe this was done because with a dead head style system you have a large column of fuel in the fuel line that is moving very slowly at idle, when you nail the throttle and dump a whole lot of fuel into the engine the rail pressure momentarily drops as the pump has to work hard to get that column of fuel moving. For arguments sake, lets say it drops 5psi momentarily that’s a flow loss of about 8.6% but if the system was operating at a lower typical pressure like 43.5 psi (3 bar) that same 5psi drop is now a loss of 11.5%.

Higher line pressures also mean less flow so lower pressures are off benefit.

September 6, 2019 at 12:08 pm #29695

September 6, 2019 at 12:08 pm #29695The Flow/Pressure thing is why I mentioned you need the fuel system to cope, even more so with a forced induction engine as you need Base+ Boost, so more boost you run the more pump you need, I run a pair of Walbro 460’s as pressure and a pair of 044’s as Lift’s, I could “probably” get away with half the pumps in my application but it’s good to have redundancy.

In the BMW I’ll lose the Lift section totally and run the pair of 460’s in the tank.

September 6, 2019 at 12:56 pm #29696Ian. How do you have you controller setup. What’s it regulating etc

I have a pierberg lift pump, low pressure high volume and 2x 460 walbros in my surge tank. I was planning on having 1 pump constant and then have the 2nd kick in after 4000.

My base pressure is 63psi then it’s boost referenced.

-

This reply was modified 4 years, 7 months ago by

cava454.

cava454.

September 6, 2019 at 1:32 pm #29698For road use I had mine staged, pump #1 and it’s lift pump via a SS relay were half speed till 2500, pump #2 and it’s lift pump were off till 3000 at half speed then ramped up to full speed at 4000, in the race car all 4 were flat out at key on.. no controller at all, single lap sprints didn’t need it.

September 6, 2019 at 1:59 pm #29699

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Lots of opinions on the benefit or not of running dual pumps. With one pump, if something happens and the pump stops, the car does too. On a two pump system if the second pump gives out it can be catastrophic. Having said that tons of cars out there running dual pump set ups. I actually have an email to Weldon asking them how they recommend setting up my controller, its there I might as well hook it up and use it. Jack Hayek from Earls who talked me through my system explained the difference in requirements fuel wise for two cars each making the same maximum hp, but one forced and one NA. Was quite enlightening.

September 6, 2019 at 2:00 pm #29700

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

For road use I had mine staged, pump #1 and it’s lift pump via a SS relay were half speed till 2500, pump #2 and it’s lift pump were off till 3000 at half speed then ramped up to full speed at 4000, in the race car all 4 were flat out at key on.. no controller at all, single lap sprints didn’t need it.

What did you use to “tell” it what rpm the engine was doing to trigger the relay. Is that an ECU thing?

September 6, 2019 at 2:11 pm #29701Built into the controllers Gary, you can get rpm activated or boost, the rpm ones are more flexible and as I run positive displacement blowers they work well.

In my case the single pair of pumps can run the engine flat out, the second pair are just overkill, I always try to double the required volume, nothing kills a blown engine quicker than a lean out under load..

September 6, 2019 at 2:39 pm #29702

VRSenator065Participant- Adelaide SA

- VR Senator LSx454 1960 Kombi (project) 1921 Nash Hot Rod (future project)

View build HERE

Posts: 5 777

Cool, I guess there is some sort of gizmo I could get as its a bit like activating a shift light.

September 6, 2019 at 2:52 pm #29703Thought you had a controller?

Ok had a look at the Weldon controllers, on/off, I also use am ecliptec shift light setup, it has some outputs you could use to drive the Weldon pump controller..

September 6, 2019 at 2:59 pm #29704For road use I had mine staged, pump #1 and it’s lift pump via a SS relay were half speed till 2500, pump #2 and it’s lift pump were off till 3000 at half speed then ramped up to full speed at 4000, in the race car all 4 were flat out at key on.. no controller at all, single lap sprints didn’t need it.

gotcha.

Wonder if there is a way so u can cycle the pumps. So u don’t wear out one more then the other??? Hmmm

September 6, 2019 at 3:02 pm #29705Don’t think it’s much of an issue, pump #1 at half speed at idle and cruise is barely working so it’s not wearing like it would running flat out, modern pumps have a great lifespan.

September 6, 2019 at 3:07 pm #29706Don’t think it’s much of an issue, pump #1 at half speed at idle and cruise is barely working so it’s not wearing like it would running flat out, modern pumps have a great lifespan.

i have to pick your brain on how I can get the one controller to half speed 1 pump and rpm activate the other

September 6, 2019 at 3:16 pm #29707Would have been really easy if you’d bought the second controller

September 6, 2019 at 5:28 pm #29710

September 6, 2019 at 5:28 pm #29710Would of been easier if you just gave it to me hahah

September 6, 2019 at 6:26 pm #29714LoL yeah there’s that…

Thought at the time you only wanted to go with the single controller…

You could always run all three pumps off the one controller by adding another SS relay then just ramp them down to the point it’s dropping pressure, closed loop will clean up any idle/cruise areas on the map.

September 22, 2019 at 11:24 am #29827Am considering changing my fuel pump to an internal one. Currently have the external 044. Means I would probably be best fitting a VN tank and then can use the standard hanger with better pump. Can anyone tell me which model tanks fit in VK commodore. Assume VN & VP will but will VR & VS fit. Seems to be more of the latter available.

Dave

September 22, 2019 at 4:49 pm #29829all the tanks vn/vp and vr/vs (v6&v8) will fit your vk dave, tank strap/s is different for IRS diff models and other difference is vn/vp has a seperate return line soldered to tank away from the fuel sender and vr/vs has both lines on the fuel sender unit.

-

AuthorPosts

You must be logged in to reply to this topic.